Undergraduate Research at Jefferson Lab

Niobium Thin Film Characterization for Thin Film Technology Used in Superconducting Radiofrequency Cavities

Student: Yishu Dai

School: St. Olaf College

Mentored By: Anne-Marie Valente-Feliciano

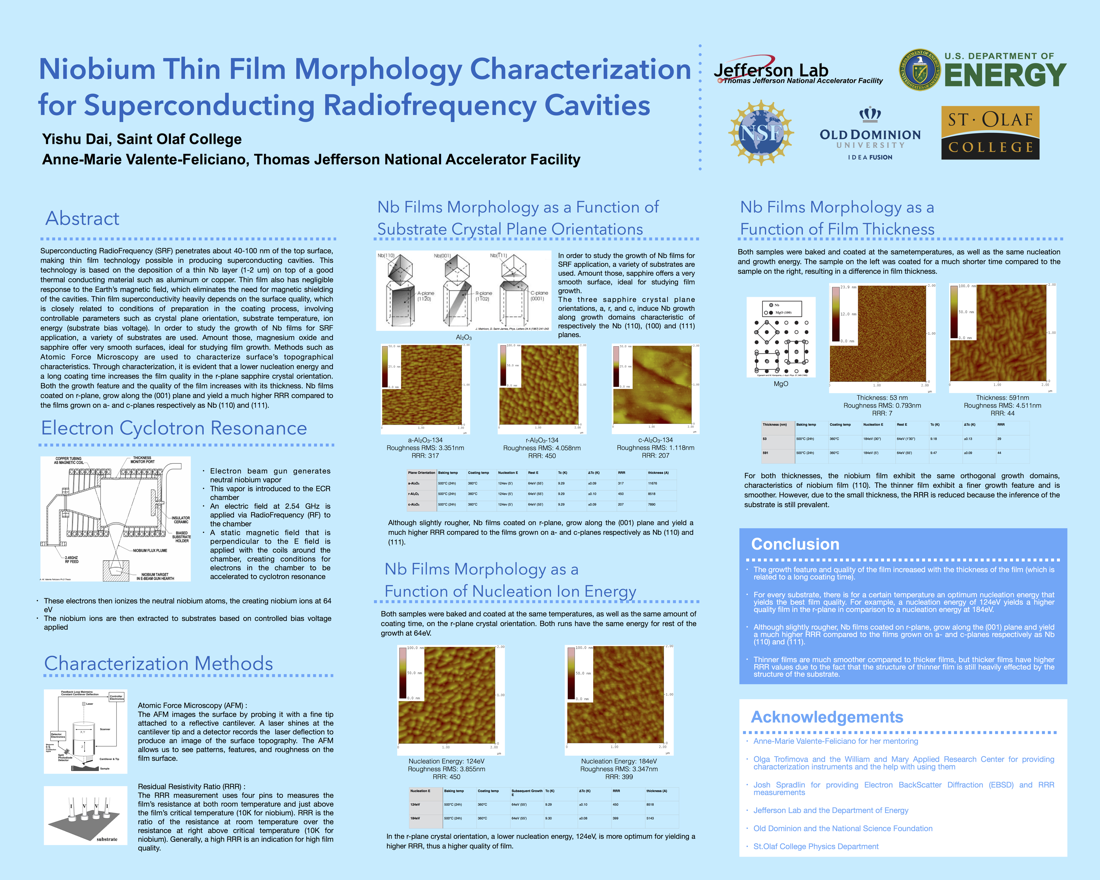

Superconducting Radiofrequency (SRF) penetrates about 40-100 nm of the top surface, making thin film technology possible in producing superconducting cavities. This technology is based on the deposition of a thin Nb layer (1-2 µm) on top of a good thermal conducting material such as aluminum or copper. Thin film also has negligible response to the Earth's magnetic field, which eliminates the need for magnetic shielding of the cavities. Thin film superconductivity heavily depends on the surface quality, which is closely related to conditions of preparation in the coating process, involving controllable parameters such as crystal plane orientation, substrate temperature, ion energy (substrate bias voltage). In order to study the growth of Nb films for SRF application, a variety of substrates are used. Amount those, magnesium oxide and sapphire offer very smooth surfaces, ideal for studying film growth. Methods such as Atomic Force Microscopy are used to characterize surface's topographical characteristics. Through characterization, it is evident that a lower nucleation energy and a long coating time increases the film quality in the r-plane sapphire crystal orientation. Both the growth feature and the quality of the film increases with its thickness. Nb films coated on r-plane, grow along the (001) plane and yield a much higher RRR compared to the films grown on a- and c-planes respectively as Nb (110) and (111).

Citation and linking information

For questions about this page, please contact Steve Gagnon.