Undergraduate Research at Jefferson Lab

12 GeV Hall A Aperture Plate and Vacuum Window Cooling System Thermal and Fluidic Analysis

Student: Cassandra Brown

School: Franklin W. Olin College of Engineering

Mentored By: Tim Michalski

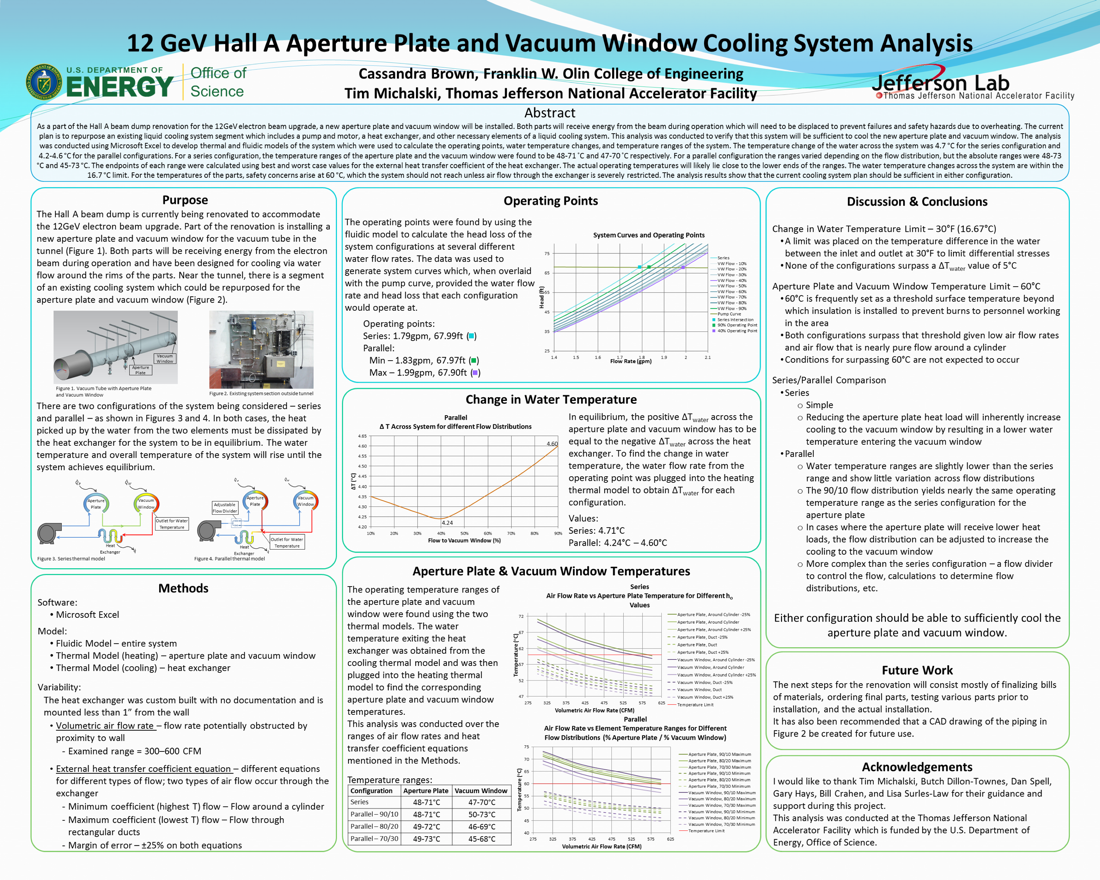

As a part of the Hall A beam dump renovation for the 12GeV electron beam upgrade, a new aperture plate and vacuum window will be installed. Both parts will receive energy from the beam during operation which will need to be dissipated to prevent failures and safety hazards due to overheating. The current plan is to repurpose an existing liquid cooling system segment which includes a pump and motor, a heat exchanger, and other necessary elements of a liquid cooling system. This analysis was conducted to verify that this system will be sufficient to cool the new aperture plate and vacuum window. The analysis was conducted using Microsoft Excel to develop thermal and fluidic models of the system which were used to calculate the operating points, water temperature changes, and temperature ranges of the system. The temperature change of the water across the system was 4.7°C for the series configuration and 4.2-4.6°C for the parallel configurations. For a series configuration, the temperature ranges of the aperture plate and the vacuum window were found to be 48-71°C and 47-70°C respectively. For a parallel configuration the ranges varied depending on the flow distribution, but the absolute ranges were 48-73°C and 45-73°C. The endpoints of each range were calculated using best and worst case values for the external heat transfer coefficient of the heat exchanger. The actual operating temperatures will likely lie close to the lower ends of the ranges. The water temperature changes across the system are within the 16.7°C limit. For the temperatures of the parts, safety concerns arise at 60°C, which the system should not reach unless air flow through the exchanger is severely restricted. The analysis results show that the current cooling system plan should be sufficient in either configuration.

Citation and linking information

For questions about this page, please contact Education Web Administrator.