Undergraduate Research at Jefferson Lab

Automatic Surface Defect Detection in Superconducting Radio Frequency Cavities using C++ and OpenCV

Student: Daniel Iriks

School: Santa Rosa Junior College

Mentored By: Grigory Eremeev

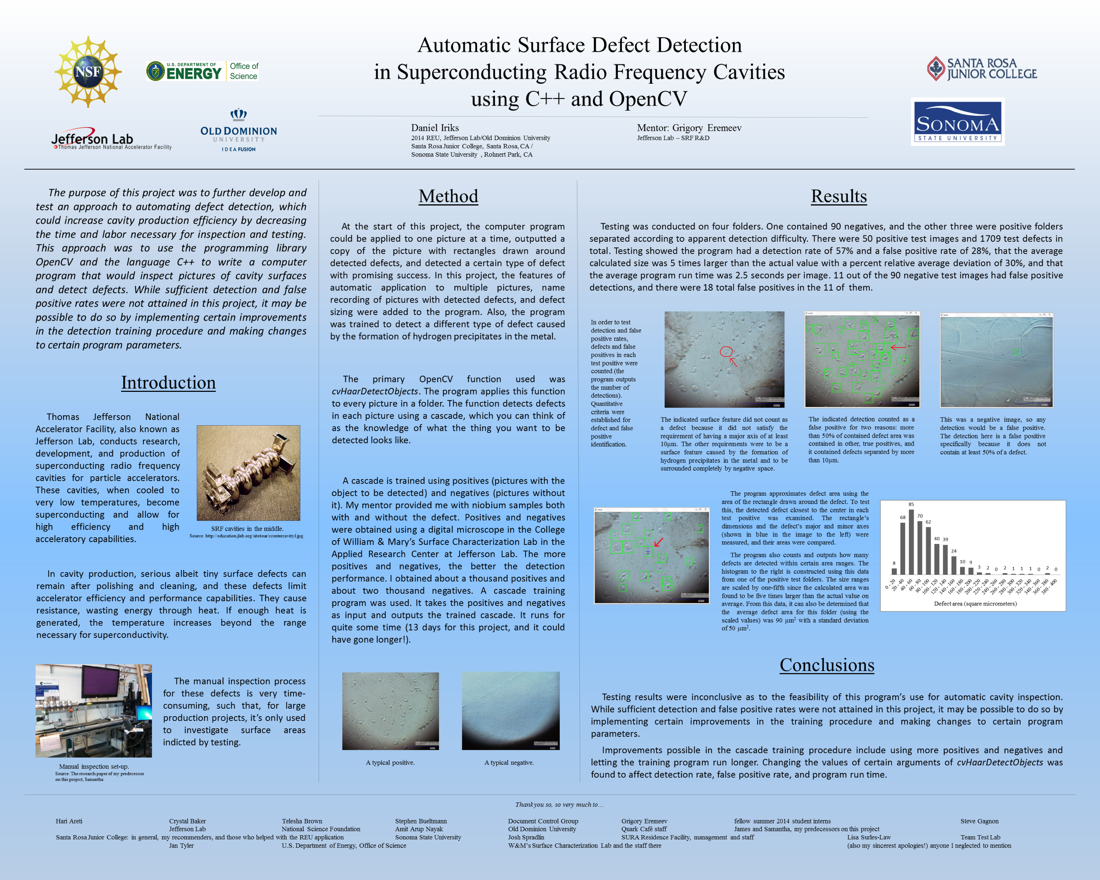

Thomas Jefferson National Accelerator Facility conducts research, development, and production of superconducting radio frequency cavities for particle accelerators. In cavity production, serious albeit tiny surface defects can remain after polishing and cleaning, and these defects limit accelerator efficiency and performance capabilities. The manual inspection process for these defects is very time-consuming. The purpose of this project was to further develop and test an approach to automating defect detection, which could increase cavity production efficiency by decreasing the time and labor necessary for inspection and testing. This approach was to use the programming library OpenCV and the language C++ to write a computer program that would inspect pictures of cavity surfaces and detect defects. In this project, the features of automatic application to multiple pictures, name recording of pictures with detected defects, and defect sizing were added to the program. Also, the program was trained to detect a different type of defect, and its performance detecting this type was tested. Testing showed the program had a detection rate of 53% and a false positive rate of 29%, that the average calculated size was 5 times larger than the actual value with a percent relative average deviation of 30%, and that the average program run time was 2.1 seconds per image. These results are inconclusive as to the feasibility of this program's use for automatic cavity inspection. While sufficient detection and false positive rates were not attained in this project, it may be possible to do so by implementing certain improvements in the training procedure and making changes to certain program parameters.

Citation and linking information

For questions about this page, please contact Education Web Administrator.