Undergraduate Research at Jefferson Lab

Analysis and Cost Comparison of Two Existing Girders to the New 80/20 Design

Student: Christopher X. Chattman

School: The University of Memphis

Mentored By: Paul Hansen

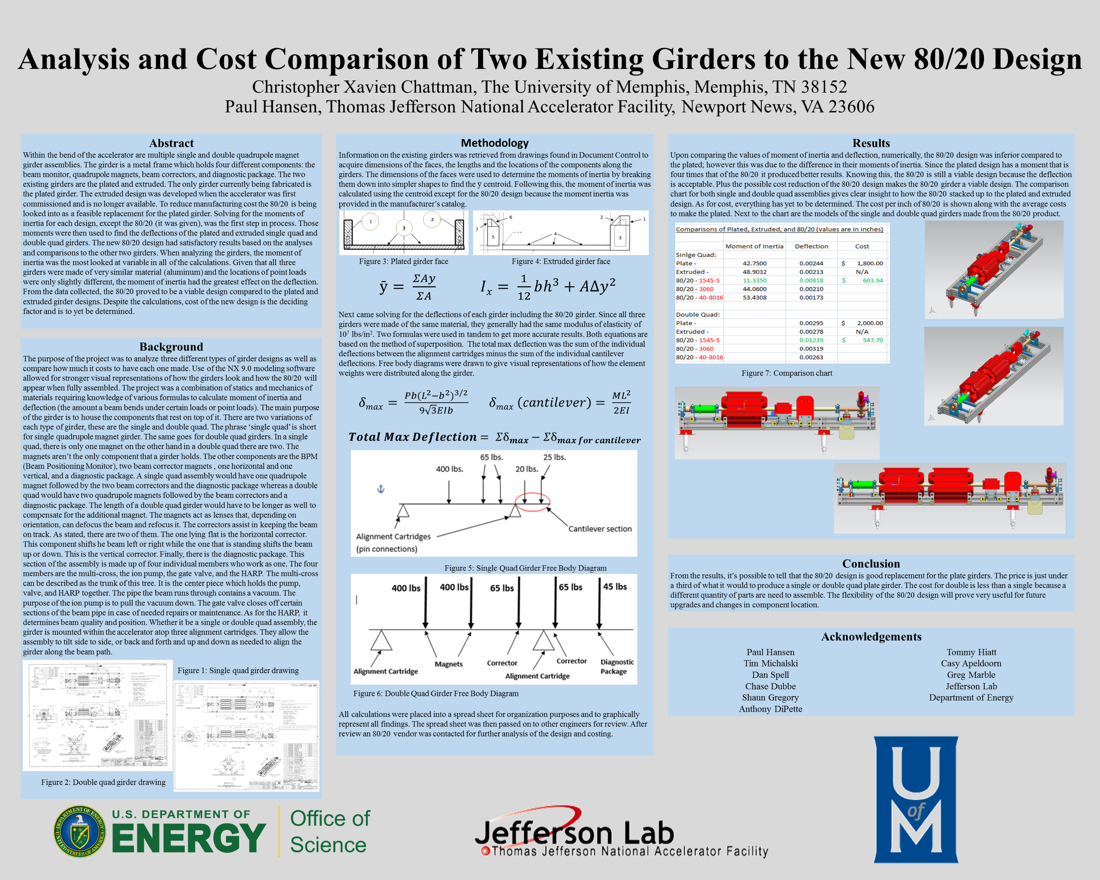

Within the bend of the accelerator are multiple single and double quadrupole magnet girder assemblies. The girder is a metal frame which holds four different components: the beam monitor, quadrupole magnets, beam correctors, and diagnostic package. The two existing girders are the plate and extruded girders. The only girder currently being fabricated is the plate girder. The extruded design was developed when the accelerator was first commissioned and is no longer available. To reduce manufacturing cost the 80/20 is being looked into as a feasible replacement for the plated girder. Solving for the moments of inertia for each design, except the 80/20 (it was given), was the first step in process. Those moments were then used to find the deflections of the plated and extruded single quad and double quad girders. The new 80/20 design had satisfactory results based on the analyses and comparisons to the other two girders. When analyzing the girders, the moment of inertia was the most looked at variable in all of the calculations. Given that all three girders were made of very similar material (aluminum) and the locations of point loads were only slightly different, the moment of inertia had the greatest effect on the deflection. From the data collected, the 80/20 proved to be a viable design compared to the plated and extruded girder designs. Despite the calculations, cost of the new design is the deciding factor.

Citation and linking information

For questions about this page, please contact Education Web Administrator.