Undergraduate Research at Jefferson Lab

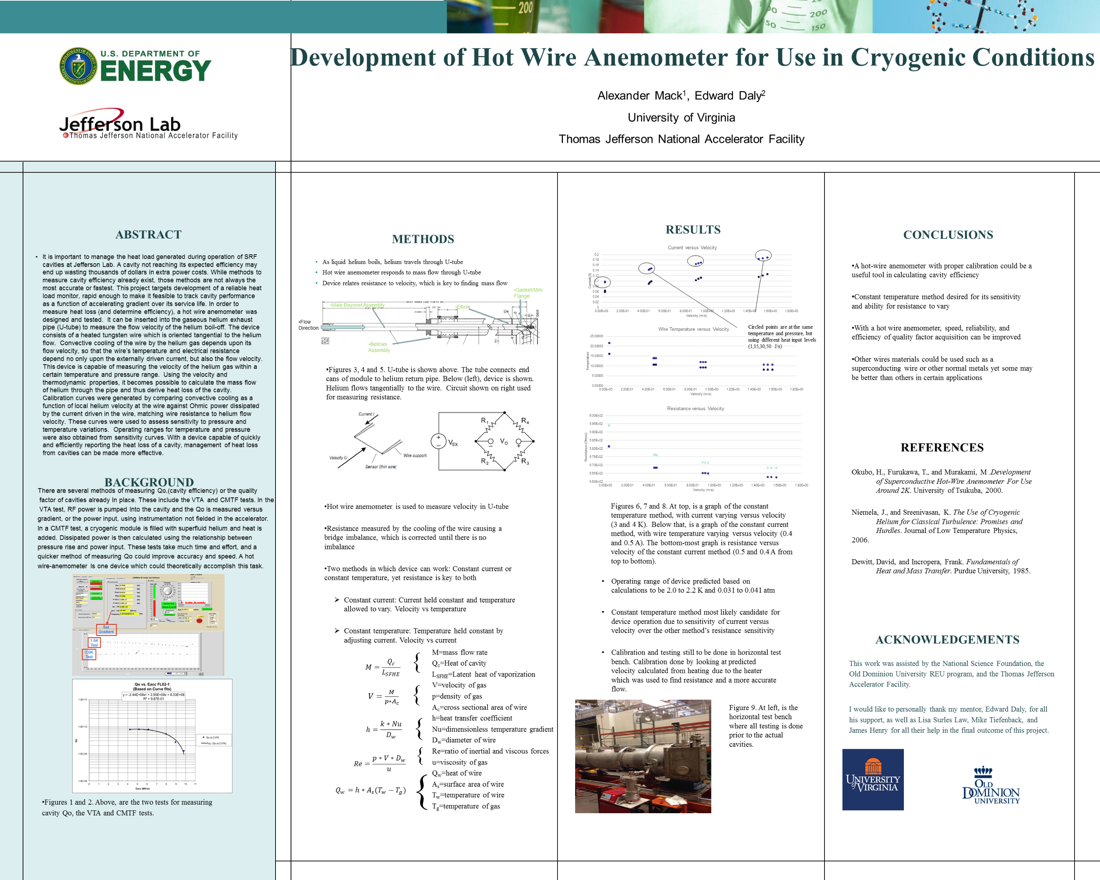

Development of Hot Wire Anemometer for Use in Cryogenic Conditions

Student: Alexander Mack

School: University Of Virginia

Mentored By: Edward Daly

It is important to manage the heat load generated during operation of SRF cavities at Jefferson Lab. A cavity not reaching its expected efficiency may end up wasting thousands of dollars in extra power costs. While methods to measure cavity efficiency already exist, those methods are not always the most accurate or fastest. This project targets development of a reliable heat load monitor, rapid enough to make it feasible to track cavity performance as a function of accelerating gradient over its service life. In order to measure heat loss (and determine efficiency), a hot wire anemometer was designed and tested. It can be inserted into the gaseous helium exhaust pipe (U-tube) to measure the flow velocity of the helium boil-off. The device consists of a heated tungsten wire which is oriented tangential to the helium flow. Convective cooling of the wire by the helium gas depends upon its flow velocity, so that the wire's temperature and electrical resistance depend no only upon the externally driven current, but also the flow velocity. This device is capable of measuring the velocity of the helium gas within a certain temperature and pressure range. Using the velocity and thermodynamic properties, it becomes possible to calculate the mass flow of helium through the pipe and thus derive heat loss of the cavity. Calibration curves were generated by comparing convective cooling as a function of local helium velocity at the wire against Ohmic power dissipated by the current driven in the wire, matching wire resistance to helium flow velocity. These curves were used to assess sensitivity to pressure and temperature variations. Operating ranges for temperature and pressure were also obtained from sensitivity curves. With a device capable of quickly and efficiently reporting the heat loss of a cavity, management of heat loss from cavities can be made more effective.

Citation and linking information

For questions about this page, please contact Education Web Administrator.