Undergraduate Research at Jefferson Lab

Optimization of Copper Electropolishing for Niobium Thin-Film Deposition

Student: Thomas Haines

School: West Virginia Wesleyan College

Mentored By: Hui Tian

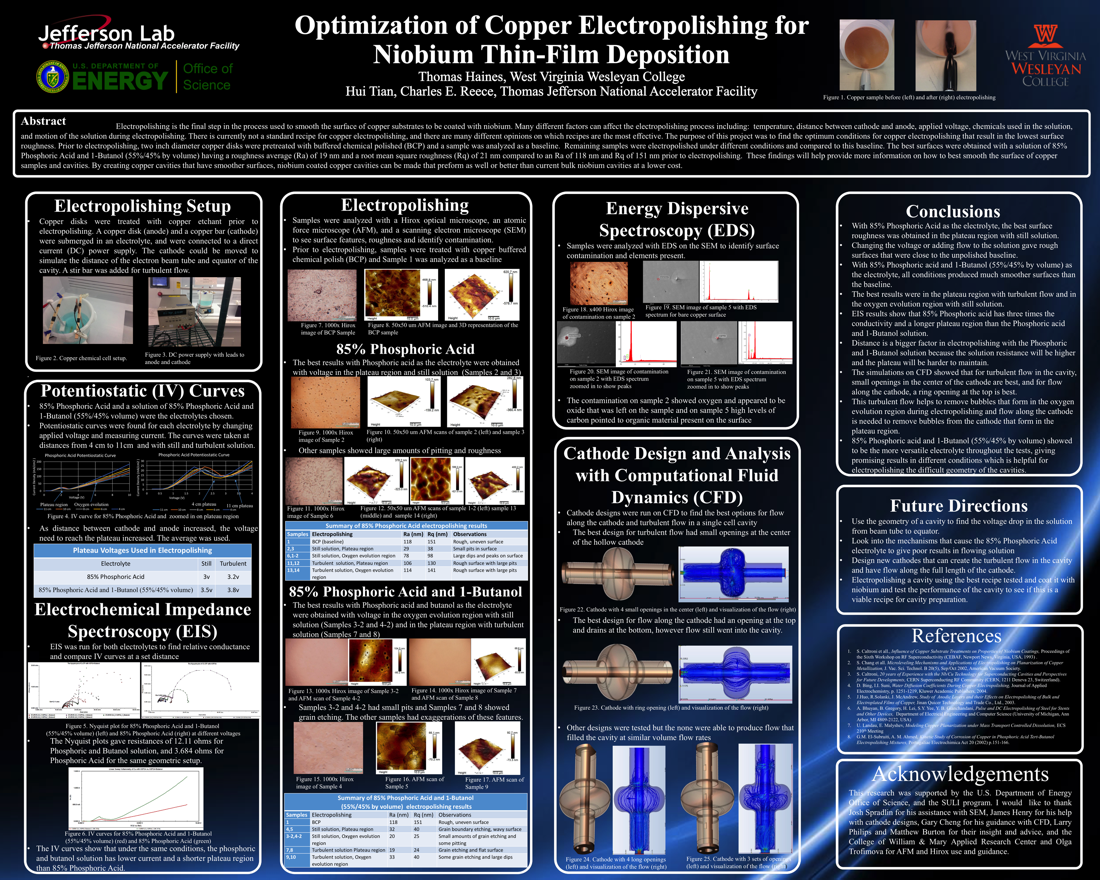

Electropolishing is the final step in the process used to smooth the surface of copper substrates to be coated with niobium. Many different factors can affect the electropolishing process including: temperature, distance between cathode and anode, applied voltage, chemicals used in the solution, and motion of the solution during electropolishing. There is currently not a standard recipe for copper electropolishing, and there are many different opinions on which recipes are the most effective. The purpose of this project was to find the optimum conditions for copper electropolishing that result in the lowest surface roughness. Prior to electropolishing, two inch diameter copper disks were pretreated with buffered chemical polished and a sample was analyzed as a baseline. Remaining samples were electropolished under different conditions and compared to this baseline. The best surfaces were obtained with a solution of 85% Phosphoric Acid and 1-Butanol (55%/45% by volume) having a roughness average of 19.083 nm and a root mean square roughness of 20.682 nm compared to an roughness average of 117.98 nm and root mean square roughness of 151.03 nm prior to electropolishing. These findings will help provide more information on how to best smooth the surface of copper samples and cavities. By creating copper cavities that have smoother surfaces, niobium coated copper cavities can be made that preform as well or better than current bulk niobium cavities at a lower cost.

Citation and linking information

For questions about this page, please contact Education Web Administrator.