Undergraduate Research at Jefferson Lab

Thermal Conductivity of Niobium and Niobium-Copper at Cryogenic Temperatures

Student: Lacey Wright

School: Virginia Polytechnic Institute and State University

Mentored By: Pashupati Dhakal

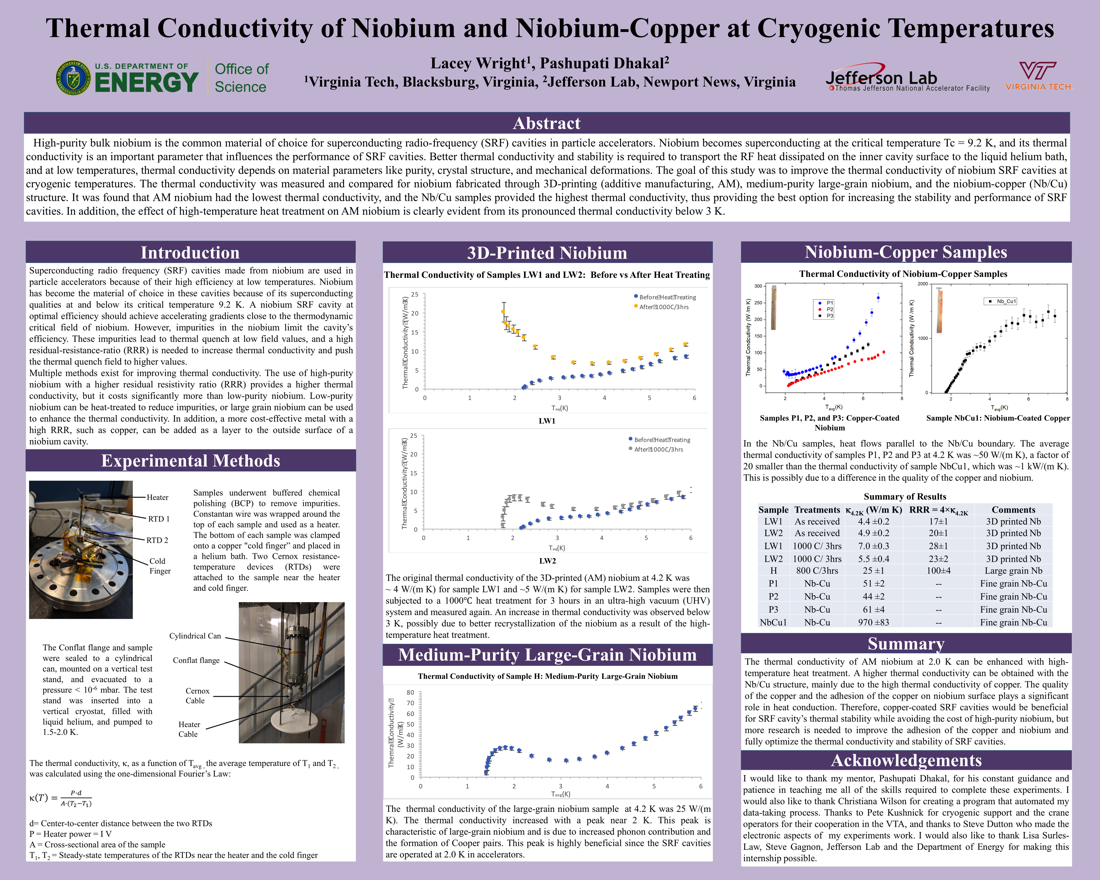

High-purity bulk niobium is the common material of choice for superconducting radio-frequency (SRF) cavities in particle accelerators because of its superconducting qualities at the critical temperature Tc = 9.2 K. Better thermal conductivity and stability in niobium is required to transport the RF heat dissipated on the inner cavity surface to the liquid helium bath. At low temperatures, thermal conductivity depends on purity, crystal structure, and mechanical deformations. The goal of this study was to evaluate the thermal conductivity of niobium samples of different purities, crystal structures and manufacturing processes. Thermal conductivity was measured for additive-manufactured (AM) niobium, medium-purity large-grain niobium, and the niobium-copper (Nb/Cu) structure. Nb/Cu samples provided the highest thermal conductivity, with the quality and adhesion of the copper on the niobium surface playing a significant role in heat conduction. Increased phonon contribution was observed in large-grain niobium due to fewer grain boundaries and decreased phonon scattering, and high-temperature heat treatment enhanced the low thermal conductivity of AM niobium at 2.0 K by reducing impurities and recrystallizing the niobium. Although successful steps were taken in improving the thermal conductivity of niobium, more research is needed to improve Nb/Cu adhesion and the heat-treatment process in order to fully optimize the thermal conductivity and stability of niobium SRF cavities.

Citation and linking information

For questions about this page, please contact Education Web Administrator.