Undergraduate Research at Jefferson Lab

Wire Stretching Automation for Detection of Electric Center for Crabbing Cavities

Student: William Fung

School: Carnegie Mellon University

Mentored By: Haipeng Wang

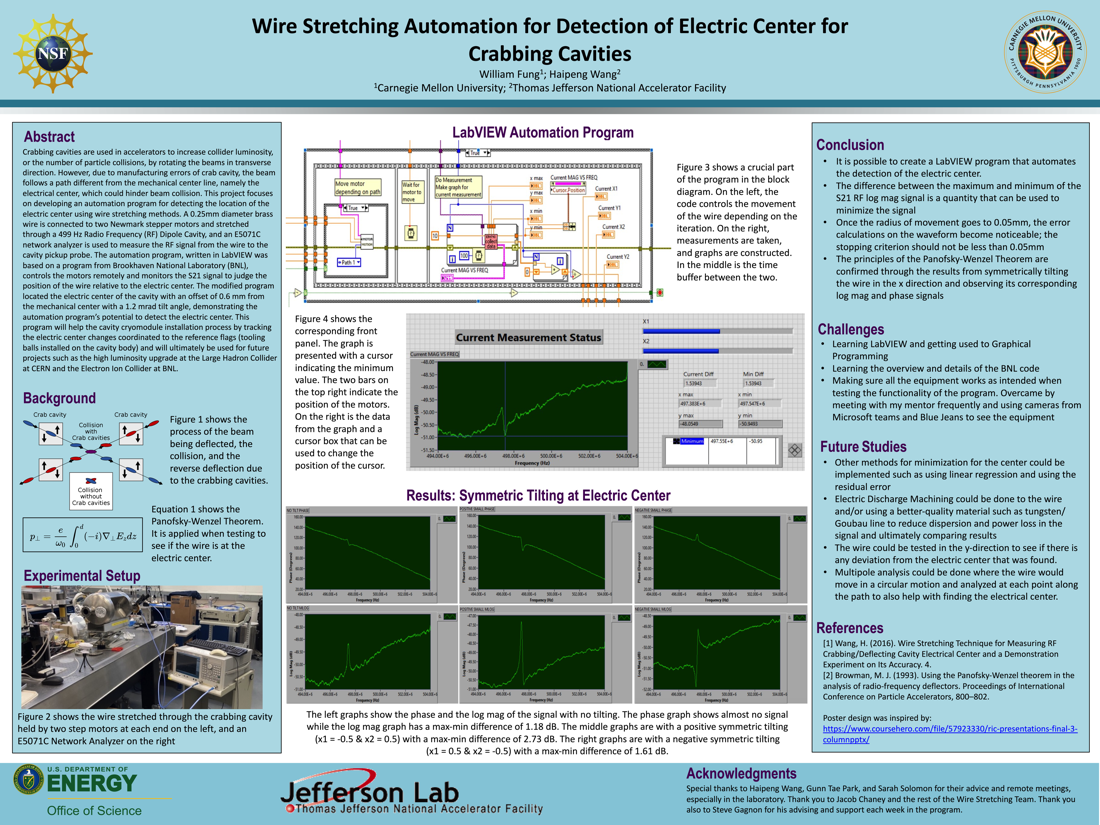

Crabbing cavities are used in accelerators to increase luminosity, or the number of collisions, by deflecting the beam in the transverse direction. However, due to manufacturing errors, the beam follows a path different from the mechanical center line, namely the electrical center, which could hinder beam deflection. Throughout the years, different methods have been employed to locate the electric center, and one way is through a method called wire stretching. This project focuses on developing an automation program for detecting the location of the electric center using wire stretching methods. A .25mm brass wire is connected to two Newmark stepper motors and stretched through a 499 Hz Radio Frequency (RF) Dipole Cavity, and an E5071C network analyzer is used to measure the RF signal from the wire and the cavity. The automation program, written in LabVIEW and based on a program from Brookhaven, controls the motors remotely and monitors the signal to judge the position of the wire relative to the electric center. The modified program located the electric center of the cavity with an offset of .6 mm from the mechanical center with a 1.2 mrad tilt angle. These results demonstrate the automation program's potential to detect the electric center. However, errors in detection have arisen as the wire got closer to the electric center due to the time-varying signal produced by the cavity. Nevertheless, the program will help the cavity fabrication process by locating the electric center in a more efficient manner and will ultimately aid future experiments such as the high luminosity upgrade at the Large Hadron Collider.

[Watch the presentation on YouTube]

Citation and linking information

For questions about this page, please contact Education Web Administrator.