Undergraduate Research at Jefferson Lab

FCAL2 Lead Tungstate Crystal Cooling Analysis

Student: Nathan Merten

School: Old Dominion University

Mentored By: Tim Whitlatch

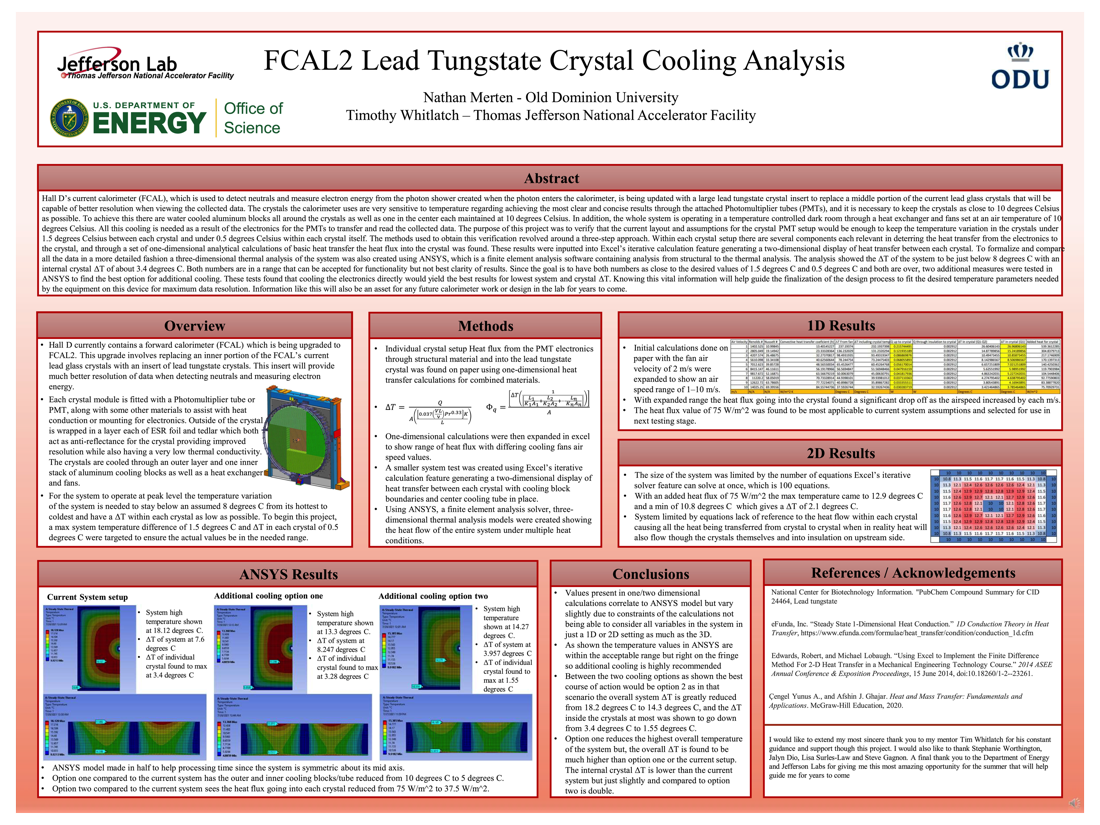

Hall D's current calorimeter (FCAL), which is used to measure the photon energy from the beam, is being updated with a larger crystal insert capable of better resolution when viewing the collected data. The crystals the calorimeter uses are very sensitive to temperature in regard to achieving the most clear and concise results through the attached Photomultiplier tubes (PMTs), and it is necessary to keep the crystals as close to 10 degrees Celsius as possible. As an added goal the desired temperature difference from crystal to crystal would be a maximum of 1.5 degrees C and 0.5 degrees C difference within each crystal itself. To achieve this there are water cooled aluminum blocks all around the crystals as well as one in the center each maintained at 10 degrees Celsius. In addition, the whole system is operating in a temperature controlled dark room through a heat exchanger and fans set at an air temperature of 10 degrees Celsius. All of this cooling is needed as a result of the electronics for the PMTs to transfer and read the collected data. The purpose of this project was to verify that the current layout and assumptions for the crystal PMT setup would be enough to keep the temperature variation in the crystals under 1.5 degrees Celsius between each crystal and under 0.5 degrees Celsius within each crystal itself. The methods used to obtain this verification revolved around a three-step approach. Within each crystal setup there are a number of components each relevant in deterring the heat transfer from the electronics to the crystal, and through a set of one-dimensional analytical calculations of basic heat transfer through each crystal setup was obtained. These results were inputted into Excel's iterative calculation feature generating a two-dimensional display of heat transfer between each crystal. To formalize and compare all the data in a more detailed fashion a three-dimensional thermal analysis of the system was also created using ANSYS, which is a finite element analysis software containing analysis from structural to the thermal analysis. In unison all three dimensions of results were able to formulate temperature results of around 6 degrees C difference between the highest and lowest temperature crystal in the system and around 3.4 degrees C difference being the highest variation of any crystal. Both numbers are far over the preset temperature goals for the system analysis, however those goals were set more on the basis of what would be desired vs what they actually are allowed to be. In this case the numbers present are defiantly in the range of workable for this system to function properly, even though them being lower would defiantly be much more ideal for the system. With that there are several factors of the system that can still be considered whose effect might not be as large as those analyzed but will still affect the resulting temperatures. Other methods of reducing the temperature can also be considered for reducing the temperature in the system such as adding additional cooling for the electronics directly or for the system as a whole. With this analysis the Hall D Fcal2 upgrade will be able to go into the next step towards completion. Knowing this vital information will help guide the finalization of the design process to fit the desired parameters needed by the equipment on this device for maximum data resolution and help the lab for years to come.

[Watch the presentation on YouTube]

Citation and linking information

For questions about this page, please contact Education Web Administrator.