Undergraduate Research at Jefferson Lab

Developing and Writing Control Logic for the High Flow Recovery Compressor

Student: Lourdes Leung

School: University of Virginia

Mentored By: Robert Norton, Josh Ballard and Brian Mastracci

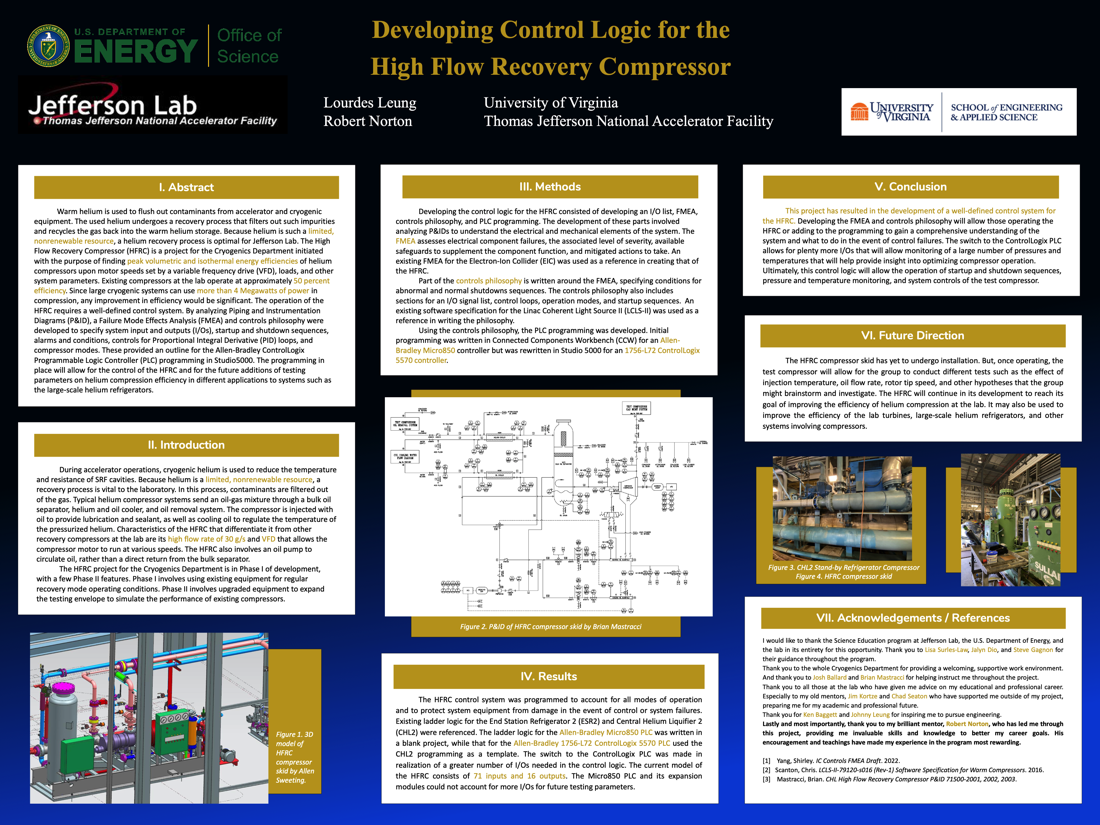

Warm helium is used to flush out contaminants from accelerator and cryogenic equipment. Because helium is such a limited, nonrenewable resource, a helium recovery process is optimal for Jefferson Lab. The High Flow Recovery Compressor (HFRC) is a project for the Cryogenics Department, initiated with the purpose of finding peak energy efficiency of helium compressors upon motor speeds set by a variable frequency drive (VFD), loads, and other system parameters. Existing compressors at the lab operate at approximately 50 percent efficiency. Since large cryogenic systems can use more than 4 Megawatts of power in compression, any improvement in efficiency would be significant. The operation of the HFRC requires a well-defined control system. By analyzing Piping and Instrumentation Diagrams (P&ID), a Failure Mode Effects Analysis (FMEA) and controls philosophy were developed to specify system input and outputs (I/Os), startup and shutdown sequences, and controls for Proportional Integral Derivative (PID) loops. These provided an outline for the Allen-Bradley ControlLogix Programmable Logic Controller (PLC) programming in Studio5000. The programming in place will allow for the control of the HFRC and for the future additions of testing parameters whose results may be applied to regular use in cryogenic systems.

Citation and linking information

For questions about this page, please contact Education Web Administrator.