Undergraduate Research at Jefferson Lab

Measurement of Hardness on Cold Rolled Niobium with Heat Treatment

Student: Millie Barron

School: Indiana University-Purdue University of Indianapolis

Mentored By: Pashupati Dhakal and Eric Lechner

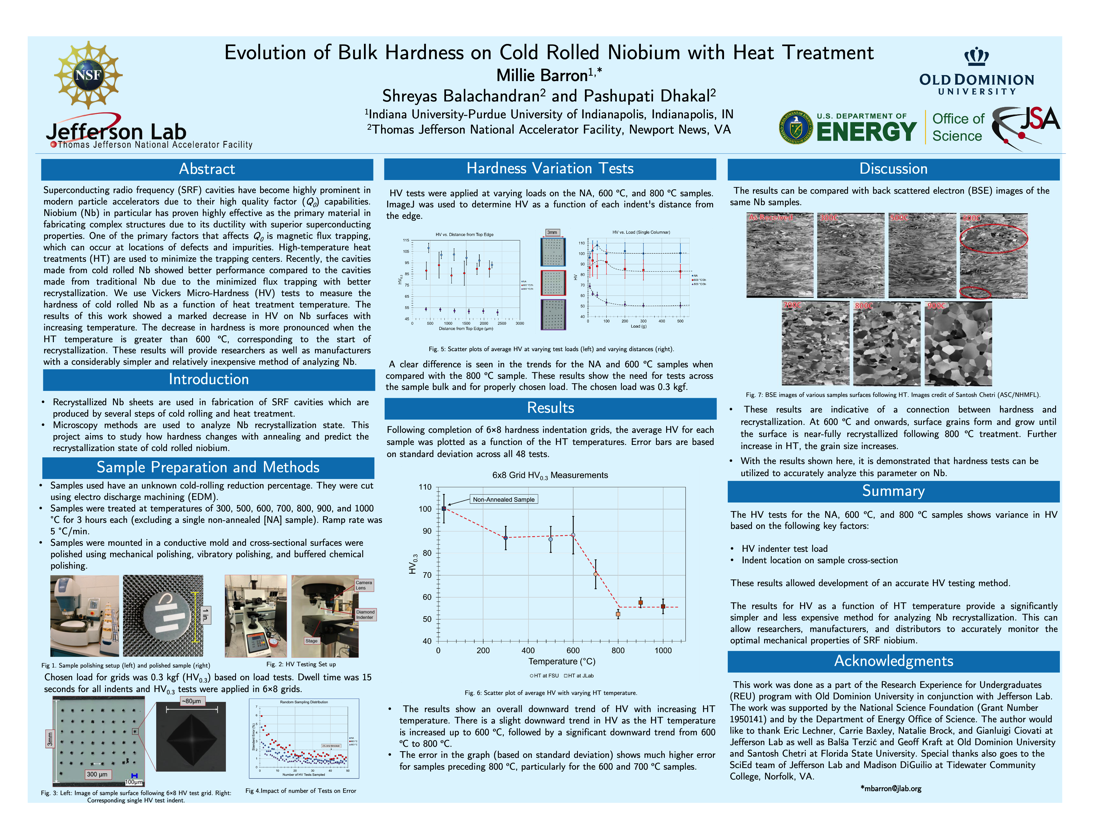

Superconducting radio frequency niobium cavities have become highly prominent in modern particle accelerators due to their high quality factor capabilities. One of the primary factors that affects the quality factor is magnetic flux trapping, which can occur at locations of defects and impurities. High-temperature heat treatments are used to minimize the trapping centers. Recently, cavities made from cold rolled niobium performed better than those made from traditional niobium. We use Vickers micro-hardness tests to measure the hardness of cold rolled niobium as a function of heat treatment temperature. This work showed a marked decrease in Vickers micro-hardness on niobium sheet cross-section with increasing temperature. The decrease in hardness is more pronounced when the temperature is greater than 600°C. The sharp decrease in hardness corresponds to the start of recrystallization. These results will provide researchers and manufacturers with a simpler and relatively inexpensive method of analyzing cold-rolled niobium.

Citation and linking information

For questions about this page, please contact Education Web Administrator.