High School Research at Jefferson Lab

Properties of Aluminum Thin Films Deposited by Thermal Evaporation

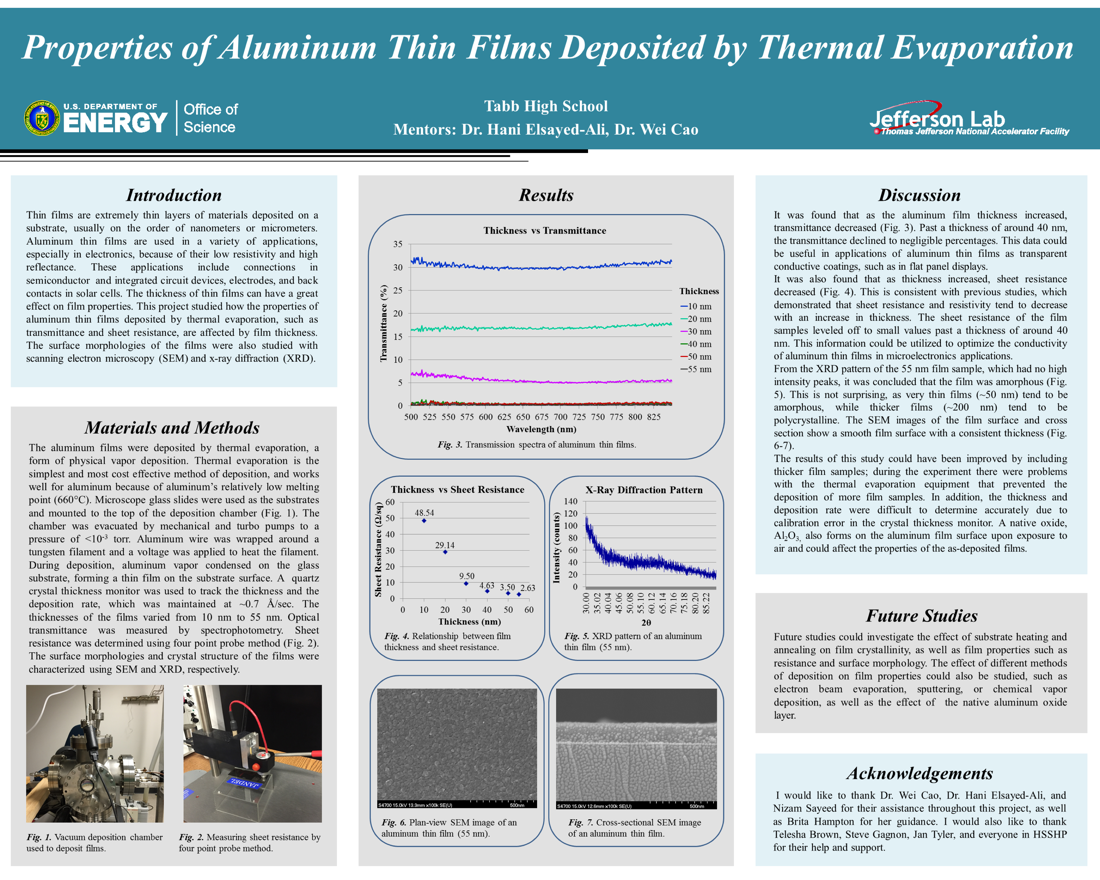

This summer I studied aluminum thin film development and testing. Aluminum thin films are used in a variety of applications in microelectronics because of their low resistivity, including as interconnections in semiconductor devices. They are also used as coatings in mirrors and as protective, anticorrosive coatings. The aluminum film samples were deposited on glass slides by thermal evaporation in a vacuum chamber, at an evaporation rate of about 0.5 angstroms/second. The films were evaporated by heating aluminum wire in a tungsten filament; once the aluminum evaporated, it rose to the top of the deposition chamber and formed a film on the glass substrate. The films were deposited from a thickness of 10 nm to 100 nm, in 10 nm increments. The resistivity of the films as a function of thickness was studied using four point probe method. Transmittance as a function of thickness was also studied using spectrophotometry.

Citation and linking information

For questions about this page, please contact Education Web Administrator.