Undergraduate Research at Jefferson Lab

Optimizing and Understanding How Bipolar Electropolishing Polishes Niobium with HF Free Electrolyte

Student: Bradley Straka

School: University of Tennessee, Knoxville

Mentored By: Hui Tian

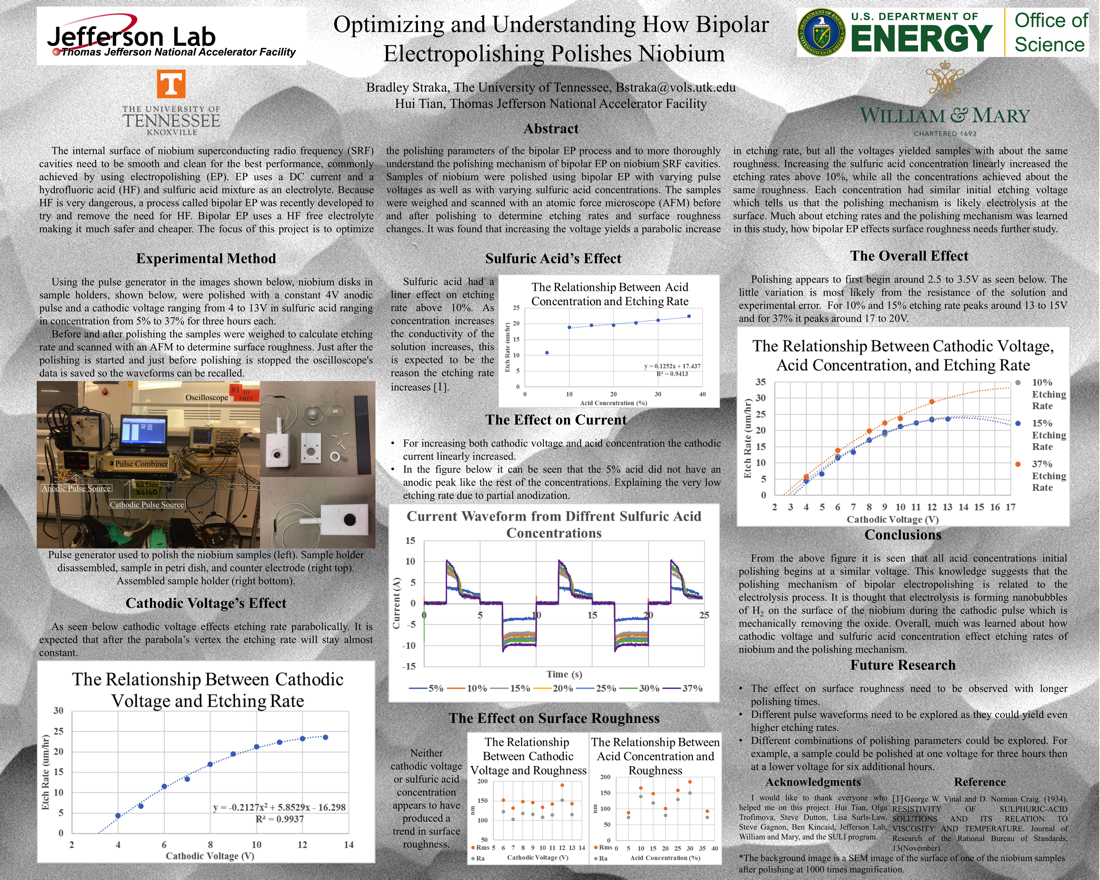

The internal surface or niobium superconducting radio frequency (SRF) cavities need to be extremely smooth for the best performance, this is commonly achieved by using electropolishing (EP). EP uses a DC current and a hydrofluoric acid (HF) and sulfuric acid mixture as an electrolyte. Because HF is very dangerous, a process called bipolar EP was recently developed to try and remove the need for HF. Bipolar EP uses a HF free electrolyte making it much safer and cheaper. The focus of this project is to optimize the polishing parameters of the bipolar EP process and to more thoroughly understand the polishing mechanism of bipolar EP on niobium SRF cavities. Samples of niobium were polished using bipolar EP with varying pulse voltages as well as with varying sulfuric acid concentrations. The samples were weighed and scanned with an atomic force microscope (AFM) before and after polishing to determine etching rates and surface roughness changes. It was found that increasing the voltage yields a parabolic increase in etching rate, but all the voltages yielded samples with about the same roughness. Increasing the sulfuric acid concentration linearly increased the etching rates above 10%, while all the concentrations achieved about the same roughness. Increasing acid concentration also slightly decreased the voltage that first caused etching. The similar initial etching voltage tells us that the polishing mechanism is likely only electrolysis at the surface. These findings tell us much about etching rates and the polishing mechanism, but very little about how effective bipolar EP is at polishing the surface. In the future, more research is needed to observe the effects of much longer polishing times to see if surface roughness is effected by different voltages and sulfuric acid concentrations. Research should also be done on how changing the pulse waveform effects etching rates and surface roughness.

Citation and linking information

For questions about this page, please contact Education Web Administrator.